手机屏幕玻璃表面缺陷视觉检测技术解决方案

发布时间:

2023-02-10 11:30

手机已经成为人们生活中的必需品,手机屏幕质量的好坏直接影响其销量,一款分辨率高、色彩呈现效果清晰、质量好的屏幕对消费者具有更高的吸引力,机器视觉检测系统很好的解决了这一问题。视觉检测系统能够准确的判断手机屏幕是否存在缺陷,以及对检测到缺陷的分类和分级。

Mobile phone has become a necessity in people's life, the quality of mobile phone screen directly affects its sales. A high-resolution, clear color rendering effect and good quality screen has a higher appeal to consumers. Machine vision detection system solves this problem well. The visual inspection system can accurately judge whether there are defects on the mobile phone screen, and classify and grade the defects detected.

传统的机器视觉检测方法虽然能够满足实时性、高效性的需求,但是其特征提取能力有限,检测效果也达不到手机屏幕质检的合格标准。在此基础之上,红宝自动化有限公司通过优化的模板匹配方法检测瑕疵,提升瑕疵的识别度,实现瑕疵的自动分类识别,结合深度卷积神经网络精确、自动的特征提取能力,突出的特征抽象和表达能力,实现了手机屏幕瑕疵的高效、准确检测,而且在检测到瑕疵的同时,也完成了对瑕疵的分类工作,避免了单独进行瑕疵分类的繁琐过程。

Although the traditional machine vision detection method can meet the requirements of real-time and high efficiency, its feature extraction ability is limited, and the detection effect can not meet the qualified standard of mobile phone screen quality inspection. On this basis, Hongbao Automation Co., Ltd. detects defects through optimized template matching method, improves the recognition degree of defects, and realizes automatic classification and recognition of defects. Combined with the accurate and automatic feature extraction ability of deep convolution neural network, outstanding feature abstraction and expression ability, Hongbao Automation Co., Ltd. has realized the efficient and accurate detection of mobile phone screen defects, Also completed the classification of defects, to avoid the tedious process of separate classification of defects.

手机屏幕表面缺陷检测系统光源选择:

Selection of light source for surface defect detection system of mobile phone screen:

光源的选择需要考虑手机屏幕以及图像采集设备的匹配性和性价比。LED灯不管是寿命还是光源稳定性都具有很大的优势,大功率LED阵列,亮度极高、线性分布,聚光行极强、超长使用寿命,大于6年等,所以本系统采用的是LED光源。

The selection of light source needs to consider the matching and cost performance of mobile phone screen and image acquisition equipment. LED lamp has great advantages in both life and light source stability. High power LED array, high brightness, linear distribution, strong focusing line, long service life, more than 6 years, etc., so this system uses LED light source.

手机屏幕表面缺陷检测系统相机选择:

Camera selection of mobile phone screen surface defect detection system:

手机屏幕玻璃表面的缺陷非常细微 ,普通的面阵相机分辨率难以达到检测的精度要求,所以手机屏幕玻璃表面缺陷检测系统选择工业CCD相机。工业CCD相机黑白线阵相机,其主要性能参数如下图所示。

The surface defects of mobile phone screen glass are very fine, and the resolution of ordinary area array camera is difficult to meet the requirements of detection accuracy, so the industrial CCD camera is selected as the mobile phone screen glass surface defect detection system. The main performance parameters of industrial CCD camera black and white linear array camera are shown in the figure below.

手机屏幕玻璃表面缺陷检测系统软件选择:

Software selection of mobile phone screen glass surface defect detection system:

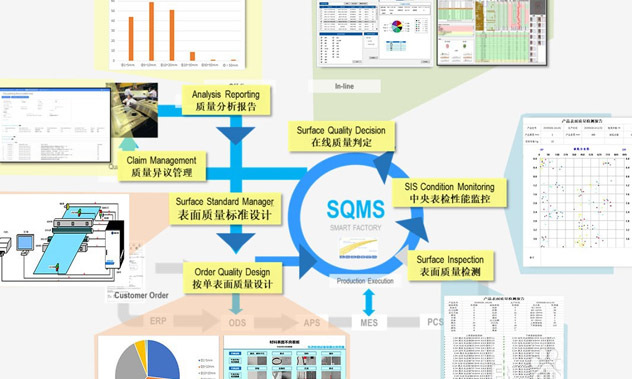

手机屏幕玻璃表面缺陷检测系统软件选择MVT-SIS视觉检测系统,MVT-SIS视觉检测系统将采集到的图像经过图像算法进行分割处理,根据缺陷图像和合格产品图像之间的灰度值差异,从而准确的识别手机屏幕玻璃表面缺陷。MVT-SIS视觉检测系统软件功能及界面可根据用户要求进行定制开发,提高了手机屏幕玻璃表面缺陷检测系统的精度和智能化水平。

The software of mobile phone screen glass surface defect detection system selects mvt-sis visual inspection system. Mvt-sis visual inspection system will segment the collected image through image algorithm, and accurately identify the surface defect of mobile phone screen glass according to the difference of gray value between defect image and qualified product image. The software function and interface of mvt-sis visual inspection system can be customized and developed according to user requirements, which improves the accuracy and intelligent level of mobile phone screen glass surface defect detection system.

The visual inspection system will make a comprehensive consideration of various factors, such as mobile phone model, screen material, size and so on, to develop a solution to respond to the defect detection of mobile phone screen.

视觉检测系统,表面缺陷视觉检测,视觉缺陷检测