工业视觉检测人工智能解决方案:视觉检测、视觉分拣和故障预测

发布时间:

2023-02-10 11:30

毋庸置疑,人工智能给制造行业带来了翻天覆地的变化,人工智能在制造业领域的三大方向:视觉检测、视觉分拣和故障预测,它所带来的变革超出我们的想象。当生产往高端发展之后,人工已经不能完全解决生产的问题,生产方式会发生巨大的变化,人工智能是工业4.0成败的关键,而企业能否抓住人工智能的机遇实现制造业转型升级将决定企业能够长久的发展下去。

There is no doubt that artificial intelligence has brought earth shaking changes to the manufacturing industry. The three major directions of artificial intelligence in the field of manufacturing industry: visual inspection, visual sorting and fault prediction, have brought changes beyond our imagination. After the development of production to the high-end, the problem of production can not be completely solved by artificial intelligence, and the mode of production will change greatly. Artificial intelligence is the key to the success or failure of industry 4.0, and whether enterprises can seize the opportunity of artificial intelligence to realize the transformation and upgrading of manufacturing industry will determine the long-term development of enterprises.

工业人工智能通过多维度学习,形成快速性、系统性及可传承性等特性。在实际操作过程中,不同个体使用同样工具可得到相同或相近的结果,系统将形成标准性解决方案,高度契合作业过程中即时响应、准确度极高、高等级安全等一系列要求。目前人工智能在制造业领域主要有三个方向:视觉检测、视觉分拣和故障预测。

Through multi-dimensional learning, industrial artificial intelligence has the characteristics of rapidity, systematicness and heritability. In the actual operation process, different individuals can get the same or similar results by using the same tool. The system will form a standard solution, which is highly suitable for a series of requirements such as immediate response, high accuracy and high-level safety. At present, artificial intelligence has three main directions in the field of manufacturing industry: visual inspection, visual sorting and fault prediction.

目前在“缺陷检测”和“预测性维护”两大方面客户接受度和需求较高,主要是因为该领域为客户痛点,能直接为客户节省大量的费用。预测性维护也有利于避免重大事故,对于安全制造和安全生产至关重要。

At present, there are high customer acceptance and demand in "defect detection" and "predictive maintenance", which is mainly because this field is a pain point for customers and can directly save a lot of costs for customers. Predictive maintenance is also conducive to avoid major accidents, which is essential for safe manufacturing and production safety.

近年来,越来越多的机器视觉落地应用,在技术与市场上的认可度不断获得提升,视觉企业成长速度加快。在工业应用领域,随着生产的柔性和自动化程度的不断提高和对质量更加严格的控制要求,企业迫切需要机器视觉来代替人工,实现定位、检测、引导、识别等功能。

In recent years, more and more machine vision applications have been applied, and the recognition in technology and market has been continuously improved, and the growth speed of vision enterprises has been accelerated. In the field of industrial application, with the continuous improvement of production flexibility and automation and more stringent control requirements for quality, enterprises urgently need machine vision to replace manual work to achieve positioning, detection, guidance, identification and other functions.

机器视觉技术是图像获取、分析、识别、检测等技术的综合,机器视觉行业经过数年的积累,不仅在规模上实现年均增速超20%,且在3D视觉、无序分拣等技术方面获得了不同程度的突破。

Machine vision technology is the integration of image acquisition, analysis, identification, detection and other technologies. After years of accumulation, machine vision industry has not only achieved an average annual growth rate of more than 20%, but also made breakthroughs in 3D vision, disorder sorting and other technologies.

人工智能技术的发展推动了机器视觉的快速应用,机器视觉检测设备是实现工业自动化和智能化的必要手段,随着机器视觉的介入,自动化设备将朝着更智能、更快速的方向发展,同时,机器视觉在各行业的渗透率也将逐渐提升。

The development of artificial intelligence technology promotes the rapid application of machine vision. Machine vision is a necessary means to realize industrial automation and intellectualization. With the intervention of machine vision, automation equipment will develop in a more intelligent and faster direction. At the same time, the penetration rate of machine vision in all walks of life will gradually increase.

其中,将近80%的工业视觉系统主要用在检测方面,包括用于提高生产效率、控制生产过程中的产品质量、采集产品数据等。

Among them, nearly 80% of the industrial vision system is mainly used in the detection, including improving the production efficiency, controlling the product quality in the production process, collecting product data and so on.

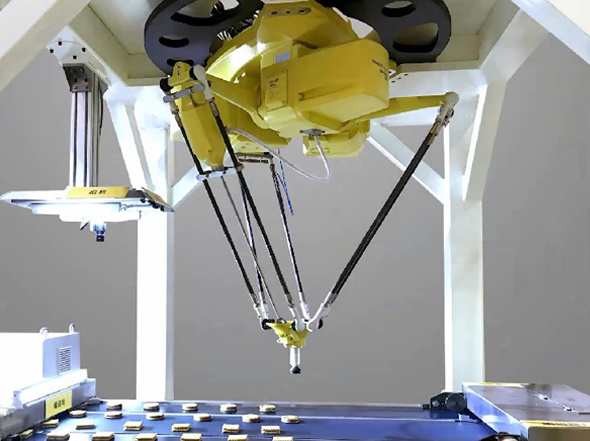

近年来,国内陆续出现了一些基于深度学习和人工智能技术解决机器人视觉分拣问题的设备,通过计算机视觉识别出物体及其三维空间位置,指导机械臂进行正确的抓取。通过3D快速成像技术,对物体表面轮廓数据进行扫描,形成点云数据后进行智能分析处理,加以人工智能分析、机器人路径自动规划、自动防碰撞技术,计算出当前工件的实时坐标,并发送指令给机器人实现抓取定位的自动完成。

In recent years, some devices based on deep learning and artificial intelligence technology have been developed to solve the problem of robot visual sorting. Through computer vision, the object and its three-dimensional spatial position can be recognized, and the manipulator can be guided to grasp correctly. Through 3D rapid imaging technology, the surface contour data of the object is scanned, and the point cloud data is analyzed and processed intelligently. Artificial intelligence analysis, robot path automatic planning and automatic anti-collision technology are applied to calculate the real-time coordinates of the current workpiece, and send instructions to the robot to realize the automatic completion of grasping and positioning.

以高性能3D相机、视觉AI算法和软件、机器人运动算法和软件为核心产品的可提供多种典型应用的参考设计和现场服务。其解决方案可使机器人厂家和集成商迅速提升人工智能能力,完成无序物体抓取、视觉引导拆垛、混合码垛、精确定位装配等应用。

With high performance 3D camera, vision AI algorithm and software, robot motion algorithm and software as the core products, it can provide reference design and field service for a variety of typical applications. The solution can make robot manufacturers and integrators quickly improve the ability of artificial intelligence, complete the application of disordered object grasping, visual guided destacking, hybrid palletizing, precise positioning assembly and so on.

基于人工智能和IOT技术,通过在工厂各个设备加装传感器,对设备运行状态进行监测,并利用神经网络建立设备故障的模型,则可以在故障发生前,对故障提前进行预测,在发生故障前,将可能发生故障的工件替换,从而保障设备的持续无故障运行。

Based on artificial intelligence and IOT technology, through the installation of sensors in various equipment in the factory to monitor the running state of the equipment, and to establish the model of equipment failure by using neural network, the failure can be predicted in advance before the fault occurs, and the parts that may have fault can be replaced before the fault occurs, so as to ensure the continuous fault-free operation of the equipment.

视觉检测系统在人工智能领域的发展已成必然的趋势,山东红宝自动化有限公司拥有经验丰富的工程师团队,能够帮助企业定制开发自动化设备,实现产品差异化,带来品牌溢价,创造企业价值优势。

The development of visual inspection system in the field of artificial intelligence has become an inevitable trend. Shandong Hongbao Automation Co., Ltd. has an experienced team of engineers, which can help enterprises customize and develop automation equipment, realize product differentiation, bring brand premium and create enterprise value advantage.

视觉检测,定制开发自动化设备