视觉检测系统中尺寸测量的原理及人工无法比拟的优点

发布时间:

2023-02-10 11:30

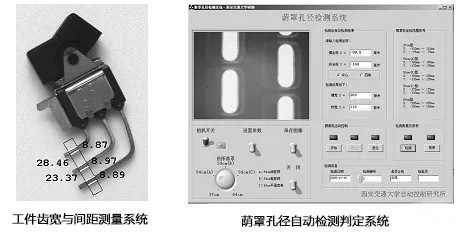

在大规模的自动化生产中,传统的尺寸测量方法已经不能满足需求,这时候机器视觉检测系统尺寸测量具有检测精度高、速度快、成本低、安装简单等优点,可以检测零件的各种尺寸,如长度、圆、角度、线弧等测量。本文将详细介绍视觉检测系统技术中尺寸测量的知识介绍。

In the large-scale automatic production, the traditional size measurement method has been unable to meet the needs. At this time, the machine vision inspection system has the advantages of high detection accuracy, fast speed, low cost, simple installation and so on. It can detect various dimensions of parts, such as length, circle, angle, line arc and so on. This paper will introduce the knowledge of dimension measurement in visual inspection system technology in detail.

工件检测的基本流程图

Basic flow chart of workpiece inspection

机器视觉尺寸测量应用实例

Application of machine vision dimension measurement

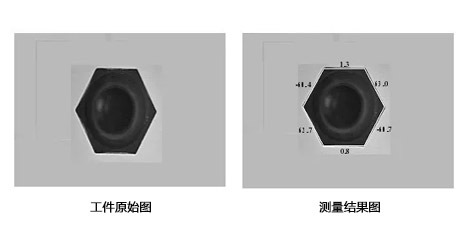

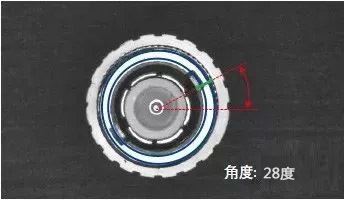

角度测量

Angle measurement

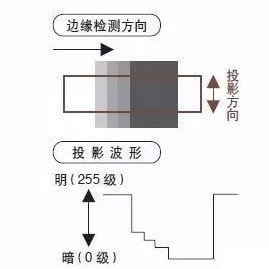

如何进行边缘检测

How to detect edge

(1)投影处理

Projection processing

投影处理是相对于检查方向进行垂直扫描,然后计算各投影线的平均浓度。

Projection processing is to scan vertically relative to the inspection direction, and then calculate the average concentration of each projection line.

投影线平均浓度波形被称为投影波形。

The average concentration waveform of projection line is called projection waveform.

算投影方向的平均浓度可以减少区域内的噪点造成的检查错误。

Calculating the average concentration of the projection direction can reduce the error caused by the noise in the region.

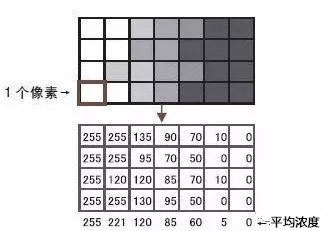

(2)微分处理

Differential processing

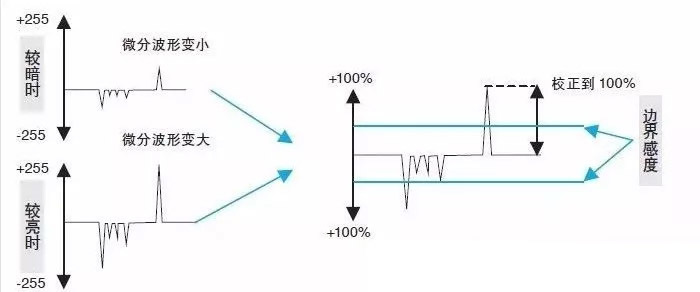

根据投影波形进行微分处理。可能成为边缘的、浓淡变化较大的部位,其微分值也较大。可以消除区域内浓度绝对值的变化所导致的影响。例:没有浓淡变化的部位的微分值是0,白色(255)→黑色(0) 时的值是-255。

Differential processing is carried out according to the projection waveform. The differential value of the part which may be the edge and the change of the shade is larger. It can eliminate the influence caused by the change of absolute value of concentration in the region. For example: the differential value of the part without the change of shade is 0, and the value of white (255) → black (0) is - 255.

(3)通过校正使微分最大值达到100%

The maximum differential value is 100% by correction

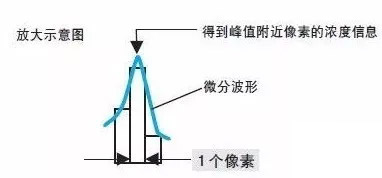

对于微分波形中最大部分的中心附近的3个像素,根据这3个像素形成的波形,进行修正演算。以1/100像素为单位测算边界位置(次像素处理)。

For the three pixels near the center of the largest part of the differential waveform, the correction calculation is performed according to the waveform formed by these three pixels. The boundary position is measured in 1 / 100 pixel (sub-pixel processing).

对于微分波形中最大部分的中心附近的3个像素,根据这3个像素形成的波形,进行修正演算。以1/100像素为单位测算边界位置(次像素处理)。

For the three pixels near the center of the largest part of the differential waveform, the correction calculation is performed according to the waveform formed by these three pixels. The boundary position is measured in 1 / 100 pixel (sub-pixel processing).

边缘检测的代表性检测应用

Representative application of edge detection

(1)利用边缘位置的各种检查

Use various checks of edge position

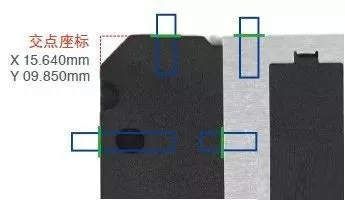

在多个部位设置边缘位置模式,测量检测对象的X座标或Y 座标。

The edge position mode is set in multiple parts to measure the x-coordinate or y-coordinate of the detected object.

(2)利用边缘宽度的各种检查

Various checks using edge width

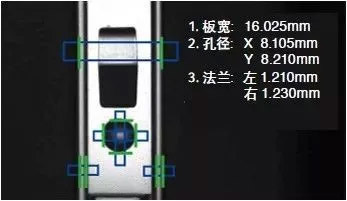

利用边缘宽度的“ 外部尺寸”模式,检测金属板的宽度、孔洞的X方向/Y方向孔径等。

Using the "external size" mode of edge width, the width of metal plate and the hole diameter in X direction / Y direction are detected.

(3)利用边缘位置圆周区域的各种检查

Various inspection of peripheral area by edge position

以圆周作为检测区域,检测切缺部位的角度(相位)。

Taking the circumference as the detection area, the angle (phase) of the missing part is detected.

(4)利用趋势边缘宽度的各种检查

Various checks using trend edge width

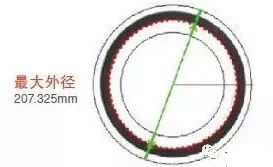

利用“圆周”区域的“趋势边缘宽度”模式,扫描环状工件的内径、评价扁平度等。

Using the "trend edge width" mode of the "circumference" area, the inner diameter of the annular workpiece is scanned and the flatness is evaluated.

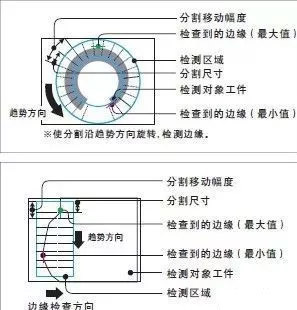

趋势边缘模式

Trend edge model

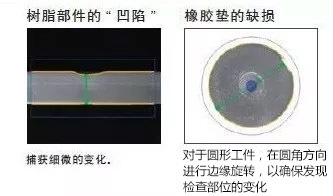

趋势边缘位置( 宽度)模式是指在扫描检查区域内较窄的边缘窗口的同时检测边缘位置。利用这种检查模式,可以对于一个窗口内的多个点进行边缘位置( 宽度) 检查,因此可以确保捕获工件的微小变化。

The trend edge position (width) mode is to detect the edge position while scanning the narrow edge window in the inspection area. With this inspection mode, edge position (width) can be checked for multiple points in a window, so as to ensure that minor changes of the workpiece can be captured.

检测原理:使小范围内的分割以小间距进行移动,检查各点的边缘宽度或边缘位置。

Detection principle: make the segmentation in a small range move with a small space, and check the edge width or edge position of each point.

提高位置检测精度的方法:缩小分割尺寸。

The method to improve the accuracy of position detection is to reduce the segmentation size.

缩短处理时间的方法:缩小分割移位幅度(移动量)。

The method to shorten the processing time is to reduce the range of segmentation shift (the amount of movement).

趋势方向:分割移动的方向。

Trend direction: the direction of the split movement.

视觉检测系统的尺寸测量技术属于非接触式的测量,不仅速度快而且测量出来的数值准确度高,相对于传统的自动化生产过程中,典型的测量尺寸的方法是千分尺、游标卡尺、塞尺等,这些测量方法测量出的结果准确度低,速度慢。

The size measurement technology of visual inspection system belongs to non-contact measurement, which is not only fast but also has high accuracy. Compared with the traditional automatic production process, the typical measurement methods are micrometer, vernier caliper, feeler gauge, etc., the accuracy and speed of these measurement methods are low.

视觉检测系统,视觉检测技术