机器视觉自动检测技术已贯穿了整个汽车制造业

发布时间:

2023-02-10 11:28

在工业4.0和制造业转型,数字化建设项目持续推进的背景下,制造业总体规模持续扩大、智能化水平不断提高,汽车制造业对机器视觉检测系统的需求度和认知度也在逐步提升,带动了中国机器视觉市场稳定增长的基础。

With the transformation of industry 4.0 and manufacturing industry and the continuous promotion of digital construction projects, the overall scale of the manufacturing industry continues to expand and the level of intelligence continues to improve. The demand and awareness of downstream industries for machine vision are also gradually improving, which has driven the steady growth of China\'s machine vision Market.

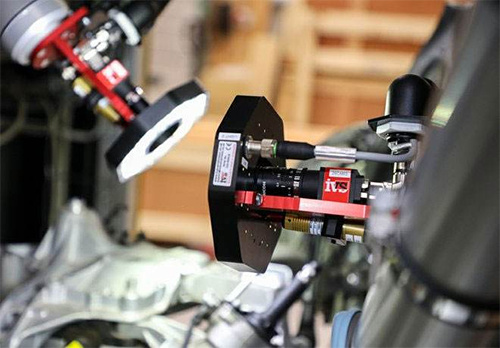

机器视觉检测系统技术的应用已贯穿了整个汽车车身制造过程,包括从初始原料质量检测发展到汽车零部件100%在线测量,再对制造过程中的焊接、涂胶、冲孔等工艺过程进行把控,最后对车身总成、出厂的整车质量进行把关。

The application of machine vision inspection system technology has run through the whole automobile body manufacturing process, including the development from the initial quality inspection of raw materials to the 100% on-line measurement of auto parts, controlling the welding, gluing, punching and other technological processes in the manufacturing process, and finally checking the quality of the body assembly and the finished vehicle.

在汽车制造行业,机器视觉几乎涉及所有系统和部件的制造流程,例如车身装配检测、面板印刷和质量检测、零件尺寸的精密测量、工业零部件表面缺陷检测等。

In the automobile manufacturing industry, machine vision involves almost all the manufacturing processes of systems and components, such as body assembly inspection, panel printing and quality inspection, precision measurement of part size, surface defect detection of industrial parts, etc.

机器视觉应用于高精度制造和质量检测,包括圆晶切割、3C表面检测、触摸屏制造、AOI 光学检测、PCB 印刷电路、电子封装等。

Machine vision is used in high precision manufacturing and quality inspection, including wafer cutting, 3C surface inspection, touch screen manufacturing, AOI optical inspection, PCB printed circuit, electronic packaging, etc.

机器视觉引入非接触测量技术,逐步发展成固定式在线测量站与机器人柔性在线测量站等在线测量系统,可严格监控车身尺寸波动,提供数据支持。

With the introduction of non-contact measurement technology, machine vision has gradually developed into online measurement systems such as fixed on-line measurement station and robot flexible online measurement station, which can strictly monitor the body size fluctuation and provide data support.

视觉引导技术逐渐渗透到汽车制造的全过程,例如引导机器人进行最佳匹配安装、精确制孔、焊缝引导及跟踪、喷涂引导、风挡玻璃装载引导等。

Visual guidance technology has gradually penetrated into the whole process of automobile manufacturing, such as guiding the robot to carry out the best matching installation, accurate drilling, welding seam guidance and tracking, spraying guidance, windshield loading guidance and so on.

机器视觉检测系统可以对产品进行制造工艺检测、自动化跟踪、追溯与控制等,包括通过光学字符识别(OCR)技术获取车身零件编码以保证零件在整个制造过程中的可追溯性,通过识别零件的存在或缺失以保证部件装配的完整性,以及通过视觉技术识别产品表面缺陷或加工工具是否存在缺陷以保证生产质量。

Machine vision inspection system can carry out manufacturing process inspection, automatic tracking, traceability and control of products, including obtaining body part code through optical character recognition (OCR) technology to ensure the traceability of parts in the whole manufacturing process, ensuring the integrity of component assembly by identifying the existence or absence of parts, and identifying the surface defects of products by visual technology Whether there are defects in the tools to ensure the production quality.

各行业自动化、智能化程度的持续加深,机器视觉检测系统设备市场在经历了短暂的“寒冬”之后,仍会呈现出稳定的增长需求。中国机器视觉行业市场主要以电子制造行业、汽车、制药、食品与包装机械、印刷机械五大应用行业的市场份额。

With the continuous deepening of automation and intelligence in various industries, the machine vision equipment market will still show a stable growth demand after a short \"cold winter\". China\'s machine vision industry market is mainly composed of electronic manufacturing industry, automobile, pharmaceutical industry, food and packaging machinery and printing machinery.

视觉检测系统